Contents

What is block machine?

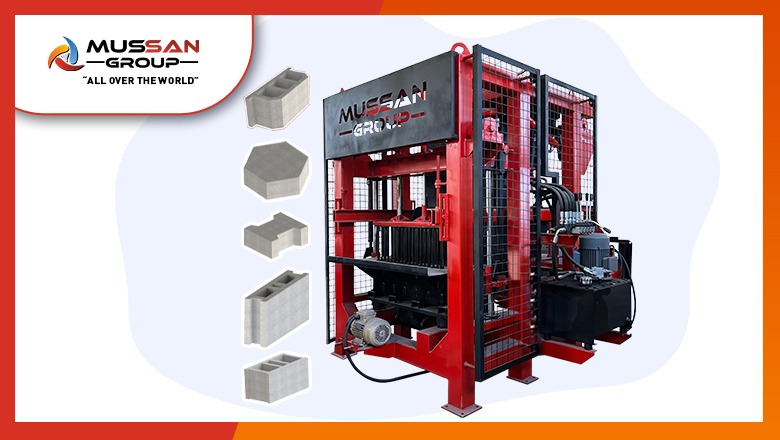

A block machine is a mechanical device that produces concrete blocks using raw materials such as cement, sand, and water. These blocks are commonly used in the construction of buildings, roads, and other structures.

Block machines come in various sizes and types, including manual, semi-automatic, and fully automatic. Manual block machines require the operator to manually put the raw materials into the machine, while semi-automatic and fully automatic machines are more automated and can produce blocks with less manual labor.

Block machines can produce a wide range of block sizes and shapes, from small paving blocks to large concrete blocks used in construction. They can also produce specialized blocks, such as interlocking blocks that can be easily assembled without the need for mortar.

Block machines are commonly used in the construction industry and can be found in many countries around the world. They are often used in countries with limited resources, as they can produce building materials locally and at a lower cost than importing them.

For our Block Machine discount campaigns “Special Offers” You can visit our page!

Here is a table summarizing the information:

| Topic | Block Machines |

| Definition | Mechanical devices that produce concrete blocks |

| Raw Materials | Cement, sand, water |

| Types | Manual, semi-automatic, fully automatic |

| Block Sizes | Wide range from small blocks to large concrete blocks |

| Special Blocks | Interlocking blocks, specialized shapes |

| Use | Construction industry, in countries with limited resources |

| Advantages | Produce building materials locally, lower cost than importing |

Our Youtube Channel Visit.

How does block machine work?

The specific operation of a block machine may vary depending on the type and model, but generally, the following steps occur:

- Raw materials, such as cement, sand, and water, are mixed together in a hopper or mixer.

- The mixture is then fed into the block machine by the help of conveyor belt.

- The machine applies pressure to the mixture, which is compacted into a mold or form.

- The mold or form is then moved along where it is cured and hardened.

- The finished blocks are then removed from the mold and stacked or stored for later use.

Here is a table summarizing the information:

| Topic | Block Machine Operation |

| Step 1 | Raw materials are mixed together |

| Step 2 | Mixture is fed into the machine by the help of conveyor belt |

| Step 3 | Machine applies pressure to mixture, compacting it into a mold or form |

| Step 4 | Mold or form is moved along where it is cured and hardened |

| Step 5 | Finished blocks are removed from the mold and stacked or stored for later use |

What is a block machine used for?

Block machines are primarily used for the production of concrete blocks that are used in the construction of buildings, roads, and other structures. These blocks can be made in a variety of sizes, shapes, and strengths to suit specific construction needs. Some common uses of concrete blocks produced by block machines include:

- Building walls: Concrete blocks are commonly used as the primary building material for walls in residential, commercial, and industrial construction projects.

- Paving: Smaller concrete blocks, such as interlocking blocks, can be used to create durable and attractive paved surfaces for walkways, driveways, and other outdoor areas.

- Retaining walls: Concrete blocks can be used to create sturdy retaining walls that hold back soil or other materials in landscaping and construction projects.

Here is a table summarizing the information:

| Topic | Uses of Block Machines |

| Primary Use | Production of concrete blocks for construction |

| Block Types | Various sizes, shapes, and strengths |

| Building | Walls, foundations, floors, and roofs |

| Paving | Walkways, driveways, outdoor areas |

| Retaining | Walls for landscaping and construction projects |

What should be considered when purchasing a block machine?

When purchasing a block machine, there are several factors to consider, such as:

- Capacity: The production capacity of the machine should match the required output for the project.

- Automation: The level of automation required depends on the scale of the project and the availability of labor.

- Power source: The power source should match the available power supply and the location of the machine.

- Block size and shape: The machine should be capable of producing the required block size and shape for the project.

- Maintenance: The machine should be easy to maintain, and replacement parts should be readily available.

- Cost: The cost of the machine should be considered, including the initial purchase price, installation costs, and operating costs.

- Reputation of the manufacturer: The reputation of the manufacturer should be considered, including their experience, customer service, and the quality of their machines.

Here is a table summarizing the information:

| Topic | Factors to Consider when Purchasing a Block Machine |

| Capacity | Production capacity for the project |

| Automation | Level of automation required for the project |

| Power source | Matching available power supply and location |

| Block size/shape | Capability to produce required block size/shape |

| Maintenance | Ease of maintenance and availability of replacement parts |

| Cost | Initial purchase price, installation and operating costs |

| Manufacturer | Reputation, experience, customer service, and machine quality |

How do concrete block machine prices vary?

The prices of concrete block machines can vary based on several factors, including:

- Machine capacity: A higher capacity machine will typically cost more than a lower capacity machine.

- Automation level: Fully automated machines with advanced features will be more expensive than manual or semi-automatic machines.

- Brand and reputation: Machines from well-known brands with a good reputation for quality and reliability may cost more than lesser-known brands.

- Location: Prices may vary depending on the location of the manufacturer and shipping costs.

- Maintenance costs: Machines that require more frequent maintenance or replacement parts may have higher long-term costs.

- Accessories and additional features: Machines with additional features or accessories such as molds, mixers, or conveyors may have higher prices.

Here is a table summarizing the information:

| Topic | Factors Affecting Concrete Block Machine Prices |

| Machine capacity | Higher capacity machines cost more |

| Automation level | Fully automated machines cost more |

| Brand and reputation | Machines from well-known brands may cost more |

| Location | Prices may vary depending on manufacturer location and shipping costs |

| Maintenance costs | Machines with higher maintenance costs have higher long-term costs |

| Accessories and additional features | Machines with additional features may have higher prices |

What features are important when buying a block machine?

When buying a block machine, there are several important features to consider, including:

- Quality of materials: The machine should be made from high-quality materials to ensure durability and longevity.

- Block production capacity: The production capacity of the machine should match the required output for the project.

- Power source: The power source should be suitable for the location and availability of power.

- Automation level: The level of automation should match the scale of the project and the availability of labor.

- Block size and shape: The machine should be capable of producing the required block size and shape for the project.

- Maintenance requirements: The machine should be easy to maintain, and replacement parts should be readily available.

- Price: The price of the machine should be considered in relation to the required features and the budget for the project.

Here is a table summarizing the information:

| Topic | Important Features When Buying a Block Machine |

| Quality of materials | High-quality materials for durability and longevity |

| Block production capacity | Matching required output for the project |

| Power source | Suitable for location and power availability |

| Automation level | Matching scale of the project and labor availability |

| Block size/shape | Capability to produce required block size/shape |

| Maintenance requirements | Ease of maintenance and availability of replacement parts |

| Price | Reasonable price for required features and budget for the project |

How to maintain the block machine?

Proper maintenance of a block machine is crucial to ensure its longevity and efficient operation. Some tips for maintaining a block machine include:

- Regular cleaning: Keep the machine clean and free from debris, dust, and other materials that could interfere with its operation.

- Lubrication: Regularly lubricate all moving parts to prevent rust and ensure smooth operation.

- Inspections: Regularly inspect the machine for wear and tear, loose parts, and other potential problems.

- Replacement of worn parts: Replace worn or damaged parts as soon as possible to prevent further damage to the machine.

- Calibration: Calibrate the machine periodically to ensure accurate production of blocks.

- Electrical components: Inspect electrical components regularly for wear and tear, and replace damaged or worn parts as needed.

Here is a table summarizing the information:

| Topic | Tips for Maintaining a Block Machine |

| Regular cleaning | Keep machine clean and free from debris and dust |

| Lubrication | Regularly lubricate all moving parts |

| Inspections | Regularly inspect the machine for wear and tear |

| Replacement of worn parts | Replace damaged or worn parts as soon as possible |

| Calibration | Periodically calibrate the machine for accurate block production |

| Electrical components | Regularly inspect electrical components for wear and tear |

What should be considered when using a block machine?

When using a block machine, there are several important considerations to keep in mind to ensure safe and efficient operation, including:

- Operator training: Ensure that operators are properly trained to operate the machine safely and efficiently.

- Safety procedures: Implement safety procedures and protocols to prevent accidents and injuries.

- Block quality: Monitor the quality of the blocks produced to ensure they meet the required specifications.

- Raw materials: Use high-quality raw materials to ensure the production of strong and durable blocks.

- Machine settings: Adjust machine settings as needed to produce blocks with the desired size, shape, and texture.

- Machine capacity: Do not exceed the machine’s capacity to avoid damaging the machine or producing subpar blocks.

Here is a table summarizing the information:

| Topic | Considerations When Using a Block Machine |

| Operator training | Ensure operators are properly trained for safe and efficient operation |

| Safety procedures | Implement safety protocols to prevent accidents and injuries |

| Block quality | Monitor the quality of blocks produced |

| Raw materials | Use high-quality raw materials for strong and durable blocks |

| Machine settings | Adjust machine settings for desired block size, shape, and texture |

| Machine capacity | Do not exceed the machine’s capacity to avoid damage and subpar blocks |

What license or permit is required for the block machine?

The specific licenses or permits required for a block machine may vary depending on the location and regulations of the area in which it is being operated. It is important to consult with local authorities and obtain any necessary permits or licenses before operating the machine.

Some common licenses or permits that may be required for operating a block machine include:

- Business license: This is a general license required to operate a business in a specific location.

- Zoning permit: A zoning permit may be required to ensure the block machine is being operated in a proper and safe location.

- Environmental permits: Depending on the location and environmental impact of the block machine, various environmental permits may be required.

- Building permits: If the block machine is being installed in a new building or structure, a building permit may be required.

- Electrical permits: If the block machine is powered by electricity, an electrical permit may be required to ensure the installation and operation of the machine meets local electrical codes.

Here is a table summarizing the information:

| Topic | Licenses or Permits Required for a Block Machine |

| Business license | Required for operating a business in a specific location |

| Zoning permit | May be required to ensure the machine is operated in a proper and safe location |

| Environmental permits | Various environmental permits may be required depending on the machine’s impact |

| Building permits | Required if the machine is being installed in a new building or structure |

| Electrical permits | Required if the machine is powered by electricity to ensure compliance with local electrical codes |

What technologies are used for the production of the block machine?

Block machines can use a variety of technologies for production, including:

- Hydraulic technology: This technology uses hydraulic pressure to mold and compress the raw materials into blocks.

- Vibrating technology: Vibrating technology uses vibration to compact and mold the raw materials into blocks.

- Pneumatic technology: Pneumatic technology uses air pressure to compress and mold the raw materials into blocks.

- Computerized technology: Computerized technology uses computer software and automation to control and monitor the block machine’s operation, resulting in more precise and efficient production.

Here is a table summarizing the information:

| Topic | Technologies Used for Block Machine Production |

| Hydraulic technology | Uses hydraulic pressure to mold and compress raw materials into blocks |

| Vibrating technology | Uses vibration to compact and mold raw materials into blocks |

| Pneumatic technology | Uses air pressure to compress and mold raw materials into blocks |

| Computerized technology | Uses computer software and automation to control and monitor machine operation |

How to transport and assemble the block machine?

Transporting and assembling a block machine requires careful planning and execution to ensure the machine is transported safely and assembled correctly. Here are some considerations and steps for transporting and assembling a block machine:

- Planning: Before transporting the machine, ensure that the transportation route is suitable and that the machine is securely fastened to the transportation vehicle.

- Unloading: When unloading the machine, use appropriate lifting equipment and follow safety procedures to prevent accidents and injuries.

- Assembly: Follow the manufacturer’s instructions for assembling the machine. This may involve installing the motor, belts, and other components.

- Electrical connections: If the machine is powered by electricity, ensure that all electrical connections are properly installed and meet local electrical codes.

- Testing: After assembly, test the machine to ensure that it is functioning properly and producing blocks that meet the required specifications.

Here is a table summarizing the information:

| Topic | Transporting and Assembling a Block Machine |

| Planning | Ensure suitable transportation route and secure fastening |

| Unloading | Use appropriate lifting equipment and follow safety procedures |

| Assembly | Follow manufacturer’s instructions for assembly |

| Electrical connections | Ensure electrical connections are properly installed and meet local codes |

| Testing | Test the machine to ensure proper functioning and block production |

What should be considered about warranty and service when purchasing a blockmachine?

Warranty and service are important considerations when purchasing a block machine, as they ensure that the machine is covered for any defects or issues that may arise during use. Here are some important points to consider regarding warranty and service:

- Warranty: Check the warranty period and terms offered by the manufacturer. A longer warranty period may provide more peace of mind and protection for the machine.

- Service: Look for a manufacturer or supplier that offers reliable and accessible service for the machine. This may include on-site service or remote technical support.

- Spare parts availability: Check the availability of spare parts for the machine, as this can impact the machine’s longevity and ease of maintenance.

- Maintenance requirements: Understand the maintenance requirements of the machine and ensure that they are manageable and fit with your operational needs.

- Training: Look for a manufacturer or supplier that offers training and support for operating and maintaining the machine, as this can reduce the risk of damage and downtime.

Here is a table summarizing the information:

| Topic | Warranty and Service Considerations for Block Machines |

| Warranty | Check the warranty period and terms offered by the manufacturer |

| Service | Look for a manufacturer or supplier that offers reliable and accessible service |

| Spare parts availability | Check the availability of spare parts for the machine |

| Maintenance requirements | Understand the maintenance requirements of the machine |

| Training | Look for a manufacturer or supplier that offers training and support for operating and maintaining the machine |