Block Manufacturing, Summer’s warmth casts a vibrant glow on construction sites across the globe, where progress takes shape block by block. Amid this flurry of activity, one name stands out—Mussan Group, an industry leader that has redefined the art and science of Block Manufacturing with a visionary approach.

Our Youtube Channel Visit.

Innovating with Mussan Group: Crafting the Future, One Block at a Time

The story of modern construction is inseparable from the concept of concrete blocks—the building blocks of architectural dreams. As the world evolves, so does the method by which we fashion our structures. And at the forefront of this evolution is Mussan Group, a trailblazer renowned for pioneering technologies that have set new benchmarks in the realm of Block Manufacturing.

Powering Progress with Precision: Meet the Markam of Mussan Group

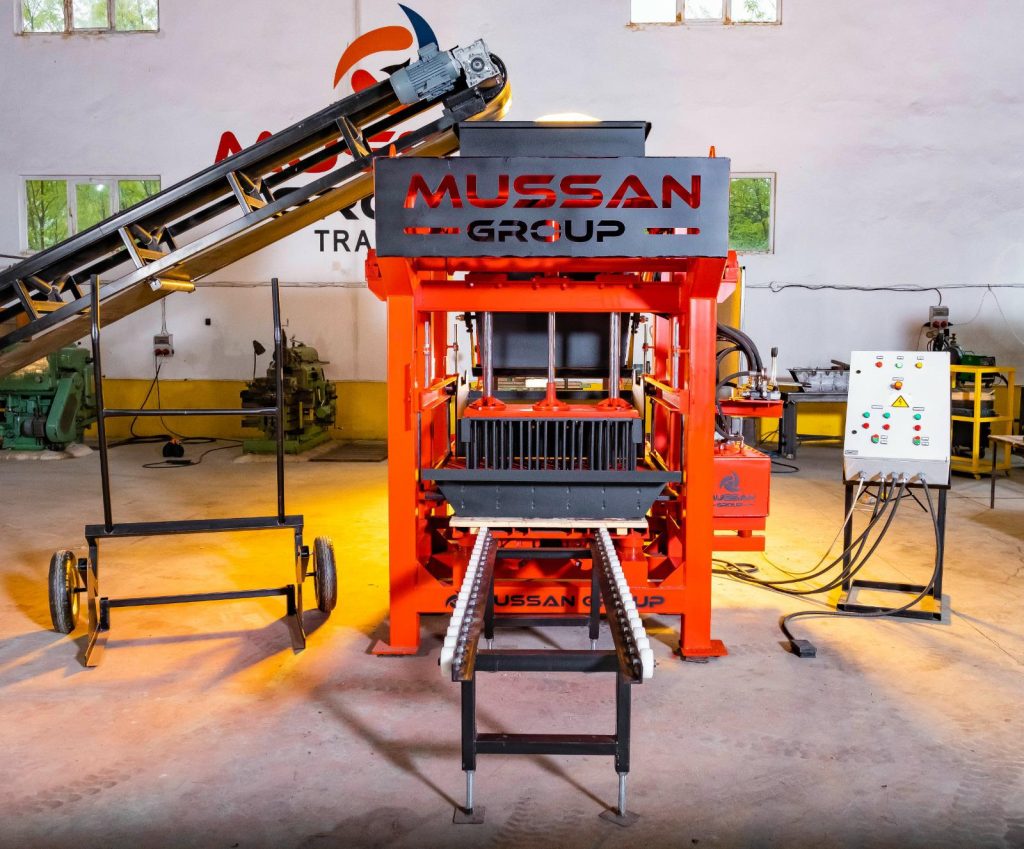

With a vision that transcends boundaries and challenges conventions, Mussan Group has etched its brand deep within the landscape of innovation. At the heart of this visionary force are the remarkable creations Block machine, Paving machine, Laying Block machine, Block machine molds, and the crown jewel, the automatic brick making machine each a testament to Mussan Group’s commitment to excellence.

In the Crucible of Creativity: Crafting Blocks, Shaping Dreams

Imagine a process where raw materials transform into solid foundations, where ingenuity molds the future. This is the essence of Block Manufacturing at Mussan Group. From the precise amalgamation of cement, aggregates, and water to the state-of-the-art machinery that breathes life into these ingredients, every step is a symphony of innovation and craftsmanship.

For our Block Machine discount campaigns “Special Offers” You can visit our page!

Empowering Construction with Ingenuity: Answering the Unveiled Questions

The journey of Block Manufacturing is not just about products; it’s about answers. Answers to questions that shape our modern infrastructure—how do we make structures more robust? More energy-efficient? Mussan Group’s solutions resonate powerfully with these queries, revolutionizing construction through H2: Innovations in Block Design.

Envisioning Green Horizons: Sustainability in Every Block

The world demands sustainable solutions, and Mussan Group answers with visionary measures. Through eco-friendly additives, recycled aggregates, and low-carbon technologies, they align their Block Manufacturing processes with nature’s pulse, sculpting a greener future for generations to come.

Precision, Perfection, Mussan Group: The New Face of Block Manufacturing

Concrete blocks aren’t just materials; they are the embodiment of progress, encapsulating innovation, strength, and vision within their sturdy frames. As you delve into the intricate world of Block Manufacturing through the eyes of Mussan Group, you embark on a journey that melds technology with artistry, redefining construction norms and crafting tomorrows that are built to last.

Conclusion: Forging Pathways to Excellence

In the realm of construction, where each block holds the promise of an architectural marvel, Mussan Group stands as a beacon of innovation. As they continue to sculpt the world with their Block Manufacturing expertise, we witness a symphony of creativity, technology, and vision a harmony that builds more than structures; it builds the future we’ve always dreamed of.*

Experience the future of Block Manufacturing with Mussan Group and witness a world where each block is a testament to excellence, precision, and sustainability.

In the realm of modern construction, concrete blocks have emerged as essential components, revolutionizing the way we build structures. Block manufacturing, a process integral to construction, involves the creation of concrete blocks used for diverse applications such as walls, pavements, and architectural features. This article delves into the intricacies of block manufacturing, from its foundational concepts to the advanced techniques that shape the construction industry.

The Fundamentals of Block Manufacturing

Block Manufacturing: Ingredients of Concrete Blocks

At the heart of block manufacturing lies the meticulous selection and preparation of raw materials. The key components include:

- Cement: An essential binding agent.

- Aggregates: Such as sand and crushed stone, responsible for strength and stability.

- Water: Which activates the cement and facilitates the chemical reaction.

- Additives and Pigments: Supplementary materials for specific properties and colors.

These materials are carefully combined to create a homogeneous mixture, ensuring optimal structural integrity and aesthetic appeal.

Block Manufacturing: Mixing and Molding

The manufacturing process kicks off with mixing, a pivotal step where the selected materials are combined. This involves:

- Batching: Precise measurement and proportioning of materials.

- Mixing: Thoroughly blending materials in a concrete mixer.

- Molding: Placing the mixed concrete into molds to shape the blocks.

Compaction within the molds eliminates air voids, resulting in a seamless, uniform surface. Advanced techniques, such as vibration or hydraulic pressure, ensure impeccable finishes.

Block Manufacturing: Curing and Strength Development

Curing is a critical phase that follows molding, allowing the concrete blocks to gain strength and durability over time. Proper curing conditions involve:

- Moisture Control: Maintaining appropriate moisture levels.

- Temperature Regulation: Controlling temperature to facilitate chemical reactions.

- Duration: Allowing sufficient time for strength development.

Innovative curing methods, including steam curing and waste heat recovery, optimize the curing process, contributing to the blocks’ quality and performance.

Advanced Techniques in Block Manufacturing

Block Manufacturing: Innovations in Block Design

The evolution of block manufacturing has witnessed the introduction of innovative designs, such as:

- Hollow Blocks: Known for thermal insulation, ideal for energy-efficient construction.

- Solid Blocks: Offering enhanced structural stability, suitable for load-bearing applications.

- Interlocking Blocks: Facilitating rapid assembly without mortar, streamlining construction.

These designs cater to both functional and aesthetic demands, revolutionizing construction possibilities.

Block Manufacturing: Automation and Technology

Modern block manufacturing has embraced automation and technology, including:

- Automated Batching: Ensuring consistent material proportions.

- Advanced Molding Techniques: Utilizing robotics and machinery for precision.

- Demolding Automation: Streamlining the demolding, handling, and packaging process.

These advancements enhance efficiency, precision, and quality control in block production.

Block Manufacturing: Sustainable Practices

The block manufacturing industry is increasingly gravitating toward sustainable practices, including:

- Eco-friendly Additives: Enhancing sustainability through material choices.

- Recycled Aggregates: Incorporating reused materials to reduce environmental impact.

- Low-Carbon Blends: Utilizing environmentally conscious cement options.

These practices align with global efforts toward greener, more environmentally responsible construction processes.

Quality Assurance and Applications

Quality Control and Testing

Ensuring the integrity of concrete blocks involves:

- Dimensional Accuracy: Precise adherence to size and shape specifications.

- Compressive Strength: Rigorous testing to ensure blocks meet required strength levels.

- Moisture Content: Monitoring moisture levels to prevent defects.

- Visual Appearance: Inspection for surface finish and aesthetics.

Quality testing extends beyond production, determining the blocks’ performance and durability in real-world scenarios.

Versatile Applications

Concrete blocks find versatile applications, including:

- Load-Bearing Walls: Providing structural support in buildings.

- Partition Walls: Dividing interior spaces efficiently.

- Foundations: Forming stable bases for structures.

- Retaining Structures: Holding back soil and preventing erosion.

- Decorative Elements: Enhancing architectural aesthetics.

These applications showcase the adaptability and functionality of concrete blocks across diverse construction needs.

Block manufacturing stands as a cornerstone of modern construction, enabling builders and designers to realize their visions with efficiency, precision, and sustainability. The journey from raw materials to high-quality concrete blocks entails a blend of science, engineering, and artistry. As innovations continue to shape the industry, block manufacturing will undoubtedly play a pivotal role in shaping the landscapes of the future.